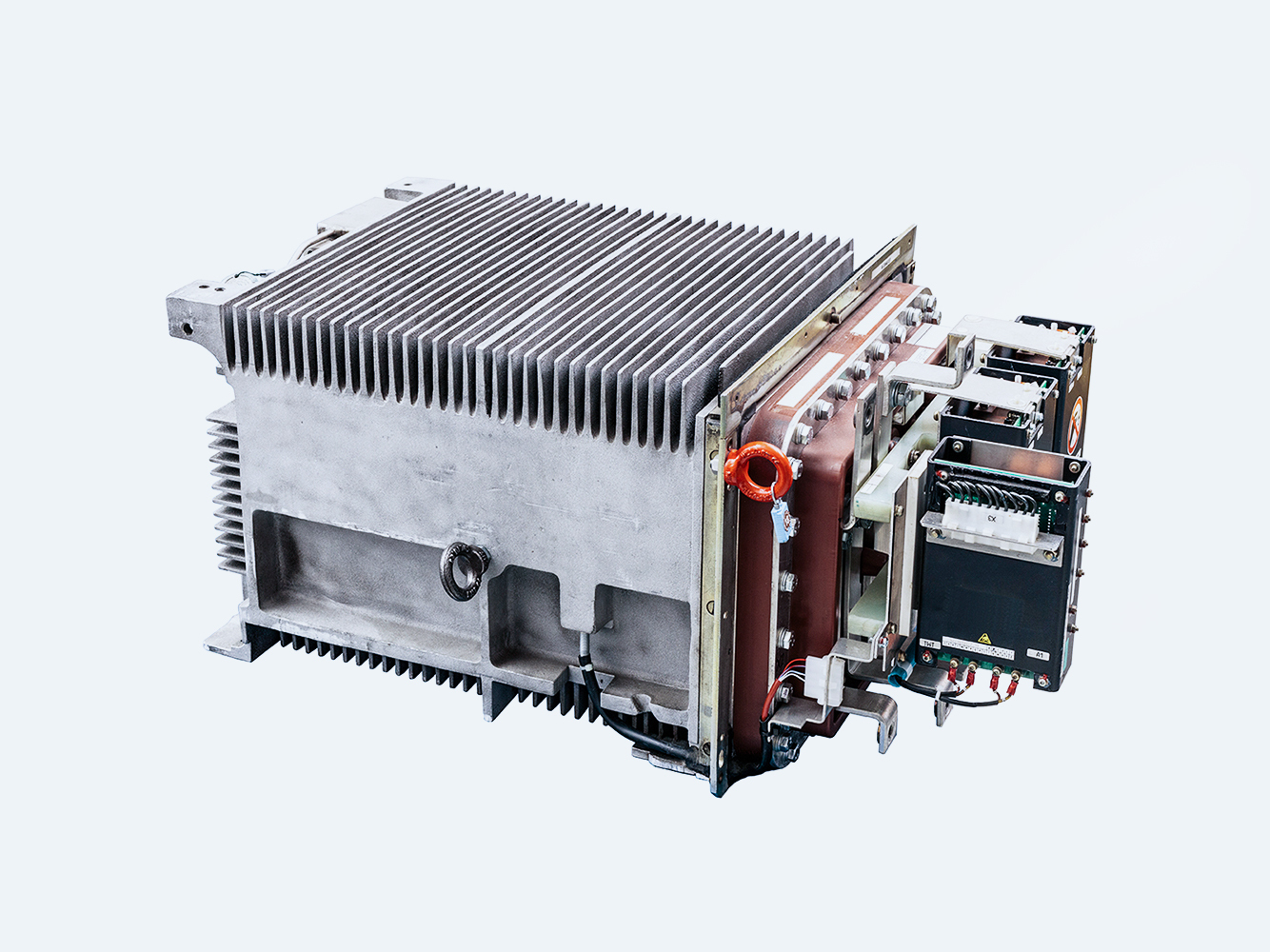

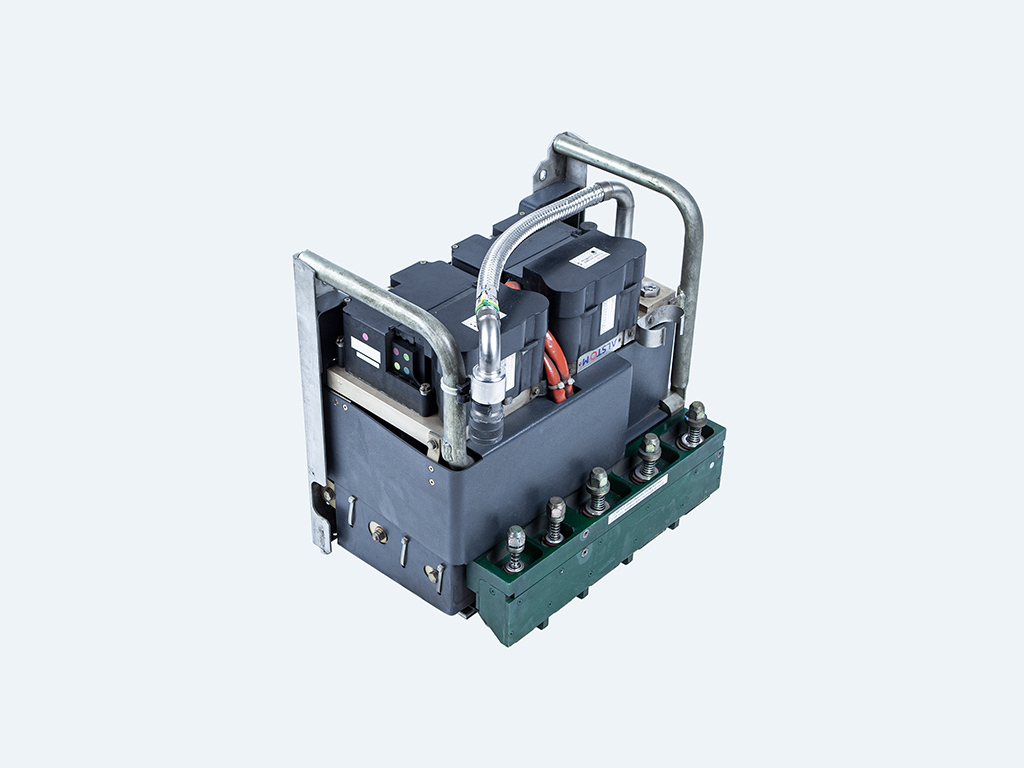

Power Converter Refurbishment

In the field of power converter module refurbishment, we offer comprehensive services that form the basis for the long-lasting and thus efficient use of your assets.

We repair power converter modules, using state-of-the-art technology and highly trained employees. Our know-how is your benefit. We stand for competently reconditioned and thus reliably functioning power converter modules in the long term.

TWO workshops,

ONE goal:

Refurbishment of your power converter modules in the shortest possible time

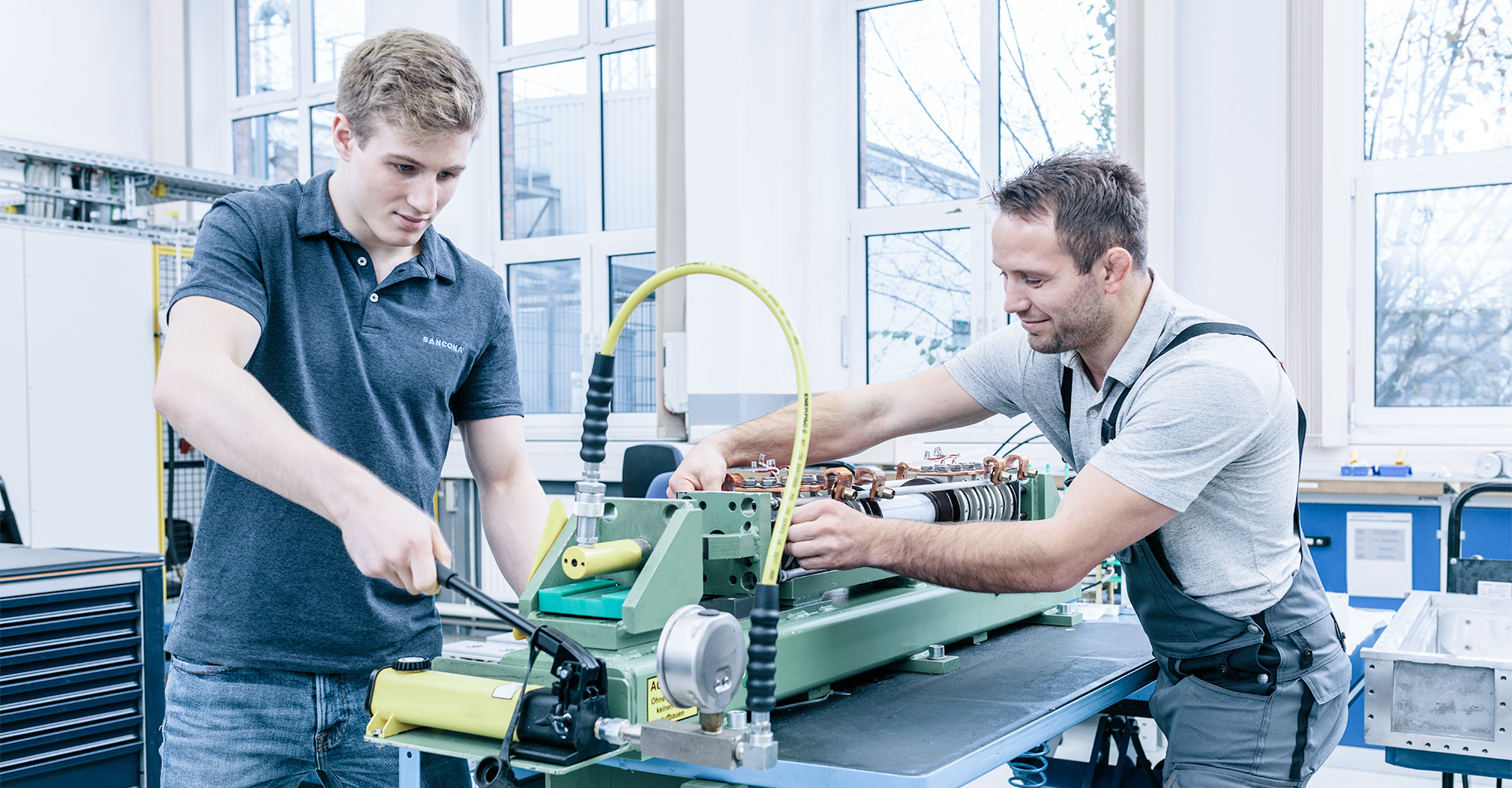

Insight into our work

Preliminary inspection of your components

Upon receipt of your assembly, we perform a detailed incoming inspection. On the basis of this inspection, we will submit a well informed refurbishment offer.

Your assemblies are inspected immediately in order to avoid idle times and to keep turnaround times as short as possible until the completion of all repair and maintenance work and subsequent return delivery.

For us, the best quality work does not come at the expense of long return times!

Partial steps of the initial diagnosis (in extracts):

- Visual pre-inspection for discoloration, fire damage, etc.

- Inspection of all mechanical components (frame, clamping assembly, BUSBARs, cooling system, etc.)

- Static testing of semiconductors and other active and passive components (e.g. GTOs or IGBTs, diodes, chokes, capacitors and resistors) for usability

Static testing

After the repair order has been placed, the new semiconductor components to be used for the repair and the other active as well as passive components are fully tested using the latest measurement technology and highly skilled employees.

Precise pre-testing - functioning components

Dielectric strength can be reliably tested: Your "old" semiconductors are already subjected to a static test during the preliminary test in order to draw conclusions about what led to the defect.

Of course, we register your components digitally and maintain their history.

The routine testing procedure comprises the following sub-steps (in extracts):

- Pre-testing of all components to be installed

- Measurement of the blocking voltage

- Pre-measurement of the disc cells (they are pre-tensioned to nominal pressing force by means of a clamping device, which can generate a pressing force of up to 40 kN, and subjected to a pre-measurement).

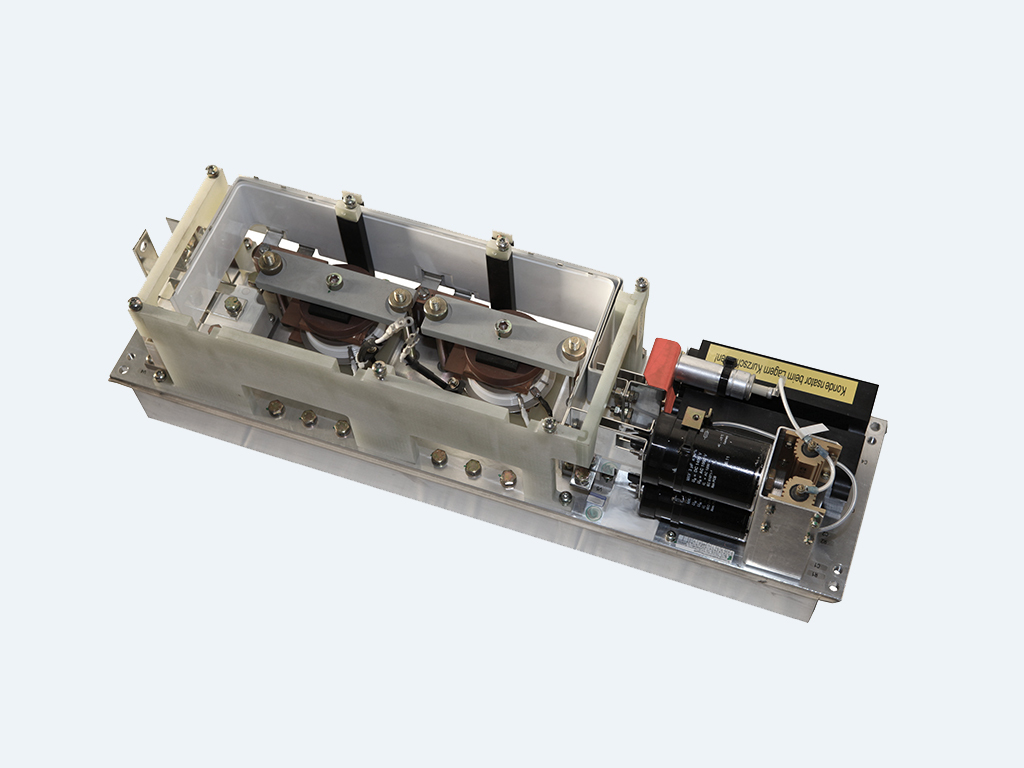

Disassembly and cleaning

Careful disassembly of your components with special attention to value-preserving work methods and gentle but thorough cleaning are the focus of our activities in this step of the refurbishment.

We assure you that we will not cause any unnecessary destruction by precise and adapted work during the reconditioning.

Success with care

In our workshops, we mainly use equipment and tools that have been specially designed and manufactured for the reconditioning of converter modules. During our many years of activity in the field of refurbishment of converter modules, we have constantly invested in the acquisition and further development of numerous special devices and tools as well as special constructions.

Because we know what we are doing!

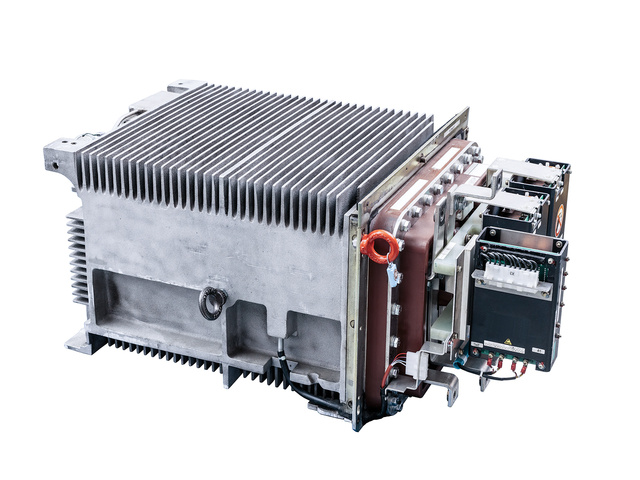

Replacement & assembly of individual components

We attach great importance to the full replacement of all pre-damaged components in close consultation with our customers in order to guarantee a smooth and long-lasting use of your assembly following the repair.

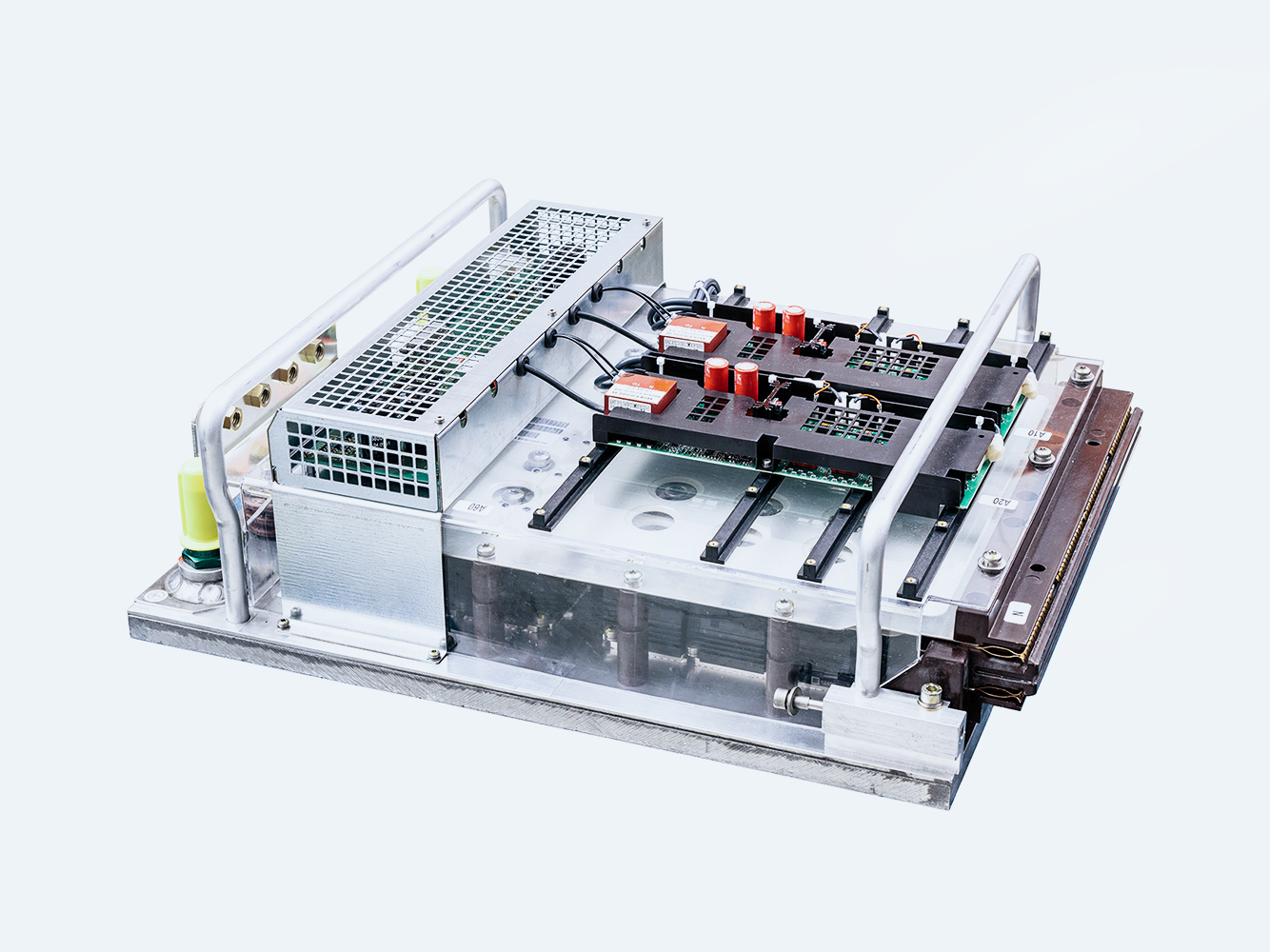

Test bay 1

For testing your components we have two test benches equipped with the latest technology. Both test benches are computer controlled and monitored. Our test technology is suitable for GTO and IGBT modules.

Key figures test field 1

- 3.750 V

- 1,050 A effective

- 2 power supplies

- continuous load maximum 2,000 A

- controlled H-bridge on a resistive load

- Controlled via optical fiber on 820 nm or current loops.

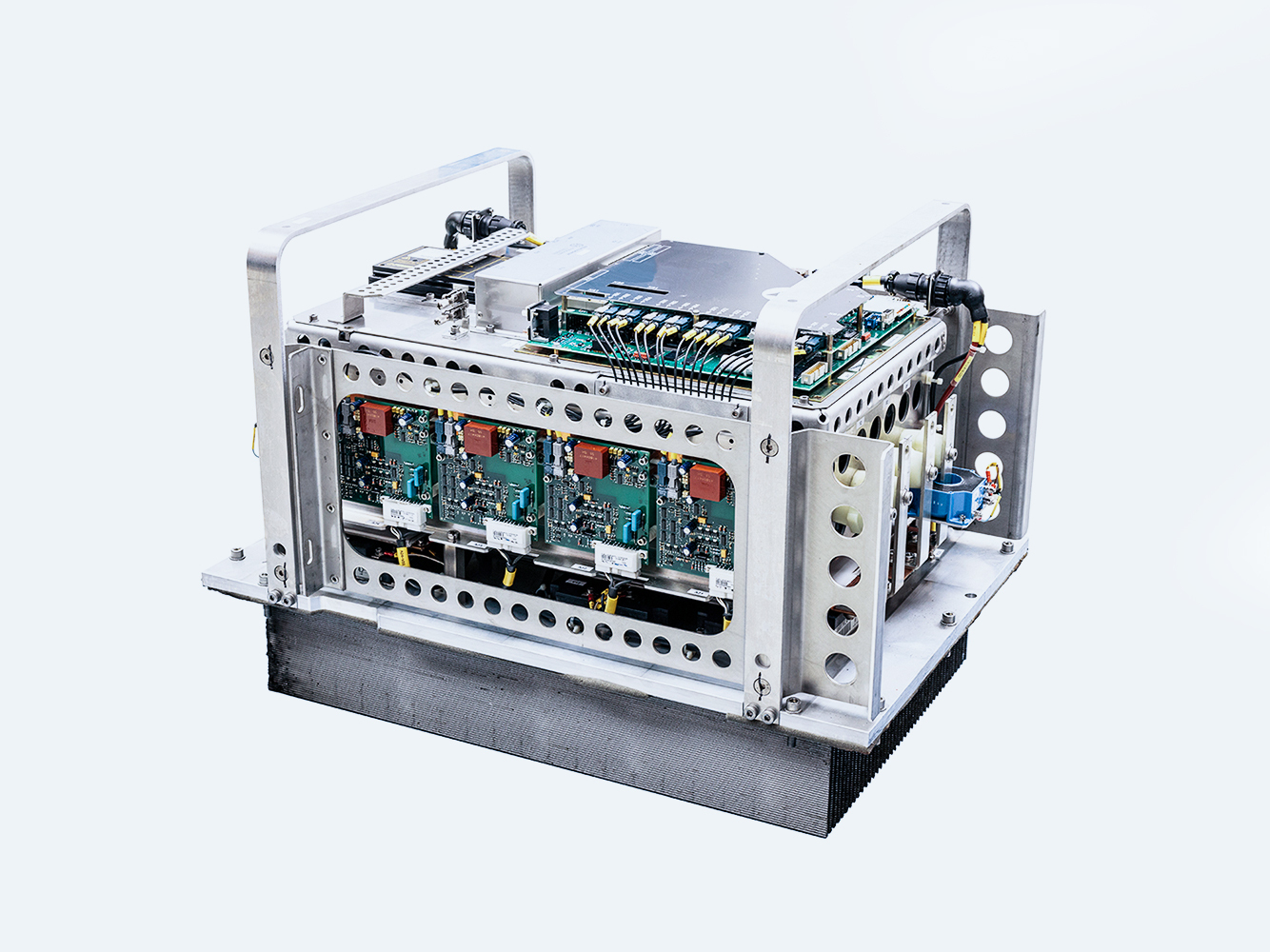

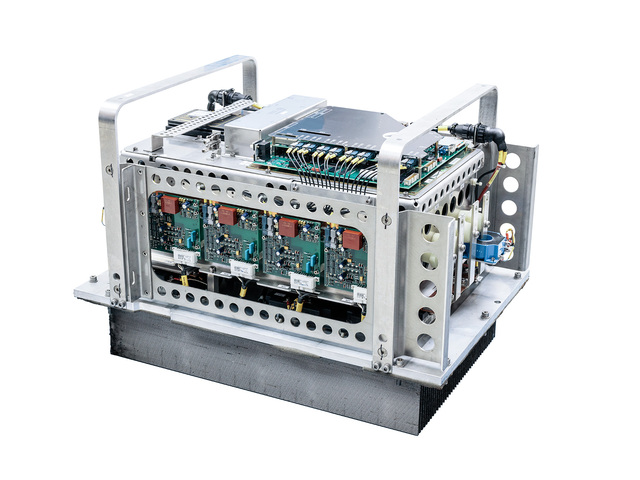

Test bay 2

For testing your components, we have two test bays equipped with the latest technology. Both test bays are computer controlled and monitored. Our test technology is suitable for GTO and IGBT modules.

Key figures test field 2

- 3.750 V

- 1,050 A effective

- 3-phase inductive load

- Control is via fiber optics on 820 nm or current loops.

Possible scope of testing for power converters

The scope of testing is determined individually in close consultation with our customers. In addition to the standard tests to be carried out for all reconditioning work, we have excellent equipment and know-how to carry out further tests tailored to your individual needs.

Well tested is half repaired!

Of course, we are happy to offer testing concepts tailored to your individual needs. Please do not hesitate to contact us.

We believe that a scope of testing that is as comprehensive as possible and adapted to your needs will help to avoid subsequent surprises during the repair process itself and to guarantee the long-lasting use of your power converter modules.

Documentation

Of course, we offer you a full documentation of the performed tests, test results, replaced components and general execution of the entire reconditioning process. This is indispensable for a smooth, long-term use of the refurbished components and an economically oriented mode of operation.

We create a comprehensive history for your refurbished power converter modules. Our focus is on a complex and complete refurbishment of your modules.

Do you have any questions?

Do you have any questions about converter reconditioning or would you like to get advice from our experts?